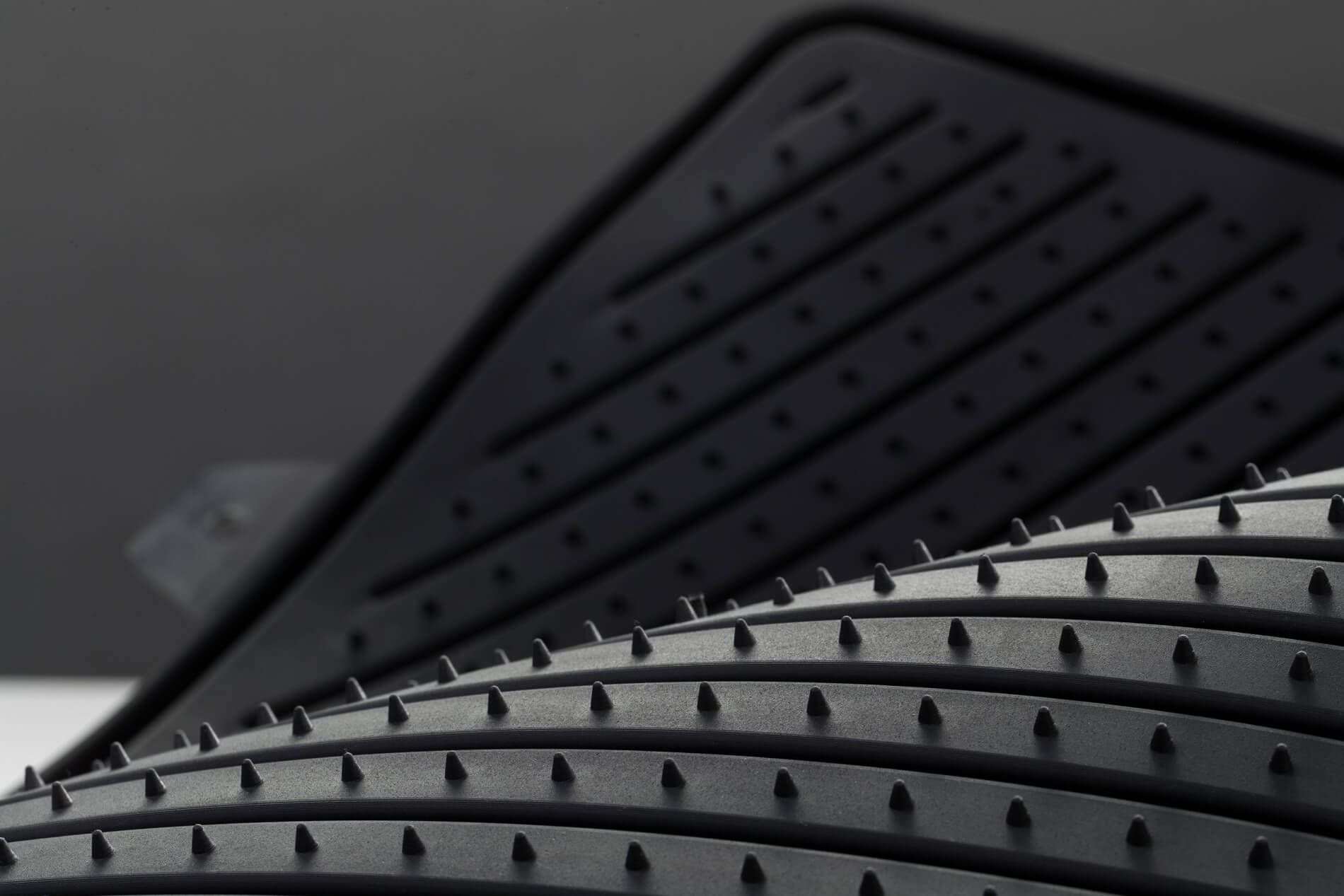

Our engineered plastic cribbing and outrigger pads are lightweight, strong and solid to support your crane. They can easily be put into position by one or two people.

Benefits of our outrigger pads:

- Do not absorb moisture and will not swell over time causing an uneven effect.

- High impact intensity with no change in strength over time.

- Good breaking elongation so will not bend or crack under extreme loads.

- Non stick surface so easily cleaned.

- Corrosion and chemical resistant.

- Weather conditions make no difference to the effectiveness of the products.

- Durable and low cost compared to steel or aluminium alternatives.

- Light weight compared to the steel alternatives.

- Will not crack, splinter or rot and are much safer to use onsite compared to the wood based pads.

- Low maintenance cost.

- Storage friendly.

Buy our Outrigger Pads directly from us

Acquire Quality Crane Outrigger Pads from Our Store

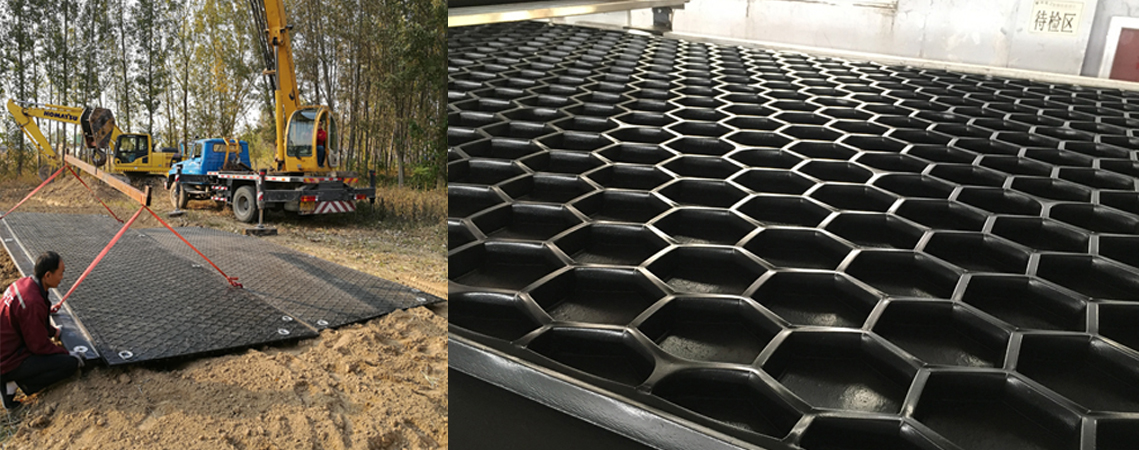

Crane outrigger pads are essential when your lifting equipment requires a stable platform. It distributes weight over a broader area, strengthening the crane’s ability to perform its core function. Using crane pads adds a degree of safety to a lifting project even though it’s not an occupational health and safety requirement. Consider the choice between using a ladder or a scaffold. Since the scaffolding spreads its weight over a larger surface area, it’s far more balanced and stable. The primary purpose of the crane mat is to displace the pressure across the surface. Without it, the crane could end up tipping over. Road Mode is a leading supplier of multiple temporary road solutions, including outrigger mats.

Benefits of Crane Outrigger Mats

You’re aware of why you require crane mats. However, with several options available in the market, it may be tough to decide which are suitable. Wooden pads are inexpensive and readily available but have significant drawbacks. The mats we provide contain recycled materials and are entirely durable.

- When you consider the environment in which you use outrigger pads, they usually contact groundwater, all forms of precipitation, and other contaminants such as motor oil, road salts, and chemicals. Wood is a porous material and quickly soaks up liquids which affects its core function. Since stability is essential, you can’t risk using this type of pad. However, our plastic pads are impervious to moisture and chemicals and continue delivering a stable platform for the crane regardless of the surface.

- Plastic outrigger pads are lightweight and easy to handle, especially when you compare them to steel and wood. Steel is naturally heavier than plastic, and wood gains weight when it absorbs liquids. Not only does this create difficulty in removing and placing the pads, but it could cause injuries to your workers.

- The strength of the material is one of the significant benefits of crane outrigger mats. It can undergo extreme stress under the weight of the crane and offers a degree of flexibility on rough terrain. You could easily maintain these pads and use them for several years to come, while storing them doesn’t require enormous space. When you compare our pads to steel and aluminium, ours is a cost-effective solution.

- With increasing requirements being placed on contractors to meet strenuous WHS/OHS/Site Safety legislation all pads are manufactured to the highest requirements and meet rigorous testing requirements all of which are supported by Technical Data Sheets outlining the lab testing undertaken.

Tips Regarding Plastic Crane Mats

Our outrigger pads are of the highest quality and capable of withstanding hefty loads. If you have a project that requires a crane on an uneven surface, we recommend using outrigger pads. It will help you keep your employees and equipment safe. When you’re looking at crane outrigger pads for sale, you must consider certain factors.

- Calculate the size of the pad you require. It should be larger than the float of the outrigger, but how much depends on several factors, including the pressure the outrigger exerts and the stability of the ground. The pad must reduce the pressure to a level that the ground below can support.

- Find a shape that suits your requirements for space and aesthetics. If you discover the ideal size, any symmetric shape will perform efficiently. Furthermore, inspect the handle to ensure that it’s sturdy and there’s no risk of it loosening.

- You can fully customise outrigger pads, so it’s wise to think about adding extras. Consider including a non-skid surface or an option with a highly visible colour such as orange or yellow. Furthermore, when you’re deploying the outrigger, ensure that it sits in the middle of the pad to distribute the weight evenly.

Outrigger Pads

Whether your business operates heavy equipment such as cranes, hoists, or other hardware that requires ground stabilisation, an investment in outrigger pads should be a top priority. The use of outriggers is essential to keeping heavy-duty machinery secure and stable when manipulating loads or moving workers up to heights. However, a shockingly large number of accidents involving this type of machinery have outriggers to blame as their cause. Why? Most often, the reason is simple: ground conditions weren’t ideal for deploying the outriggers directly onto the surface. There are other concerns to consider, too, such as potential damage to a client’s property.

At Road Mode, we’ve produced crane outrigger mats that are easy to use, highly cost-effective, and, most importantly, incredibly durable. With a stack of these pads in your inventory, any work crew will have at their disposal the most effective means of securing equipment on the job site before beginning any activity. Let’s take a closer look at why you should invest in crane outrigger pads for sale and what makes Road Mode products the right choice.

The Importance of Using Outrigger Pads in Australia

Although it is not uncommon to see heavy equipment operating without the use of any pads, it is not the wisest choice. There are many good reasons to deploy this simple hardware on your job site. Why are they so important?

- As mentioned, they can play a crucial role in safety on the site. Ground conditions are not always suitable for achieving stability with the hydraulic outriggers. Our pads provide a smooth and continuous contact surface for achieving the strong support your teams need.

- Outriggers apply a huge amount of pressure to the surface below them. Unprotected surfaces such as concrete, asphalt, and loose soil can easily collapse or give way under this pressure — creating both a hazard for the operator and unacceptable damage to the site itself.

- Pads help you protect your equipment along with the site and your workers. If the machinery becomes unsupported, it could lean or even topple over, potentially causing serious damage.

What Sets Road Mode Apart Regarding Crane Outrigger Pads?

An investment in crane outrigger mats may be a smart move for a construction-related business or crane operator. Why choose Road Mode when you decide to move forward with that purchase? Here’s how we stand apart:

- The materials we select are incredibly strong, making our mats capable of withstanding huge amounts of pressure from outriggers. Our choice of TERRA FIRMA PE1000 yields more than 11 times the strength of PE500, translating into a cost-effective investment.

- Our products require very little maintenance, are easy to clean, and stack easily, so they do not take up valuable storage space within your existing space limitations.

- We’re capable of supplying pads to suit varying size requirements, and we take pride in delivering quick turnarounds for our clients.

A Short Buyer’s Guide to Outrigger Mats

Is there anything specific you should keep in mind when exploring our crane pads for sale online? We’ve created the following quick reference guide to give you a running start on making a purchase that’s appropriate for your needs:

- First, consider the weight you need to support with a pad. The equipment you operate should specify the amount of force exerted by the outrigger pads. Many of our pads are rated for dozens of tonnes, but please ask about specific capacities.

- Next, choose pads of the appropriate size. There should be plenty of additional space around the outrigger so that the force evenly distributes across the mat’s surface area.

- Finally, determine the number of pads you will need. Consider purchasing more than just the minimum amount that corresponds to the number of outriggers you need to support to keep spares on hand or to support future expansions of your equipment pool.

About Road Mode

Founded nearly 40 years ago, Road Mode is an Australian-owned and operated business supporting builders and other industries with recycled plastic solutions for enhancing equipment stability. Committed to sustainability, quality, and top-tier customer service, we’re always happy to chat with potential clients about our Oz Pads and other related products’ unique properties. Contact us today for further details and information about how to order.